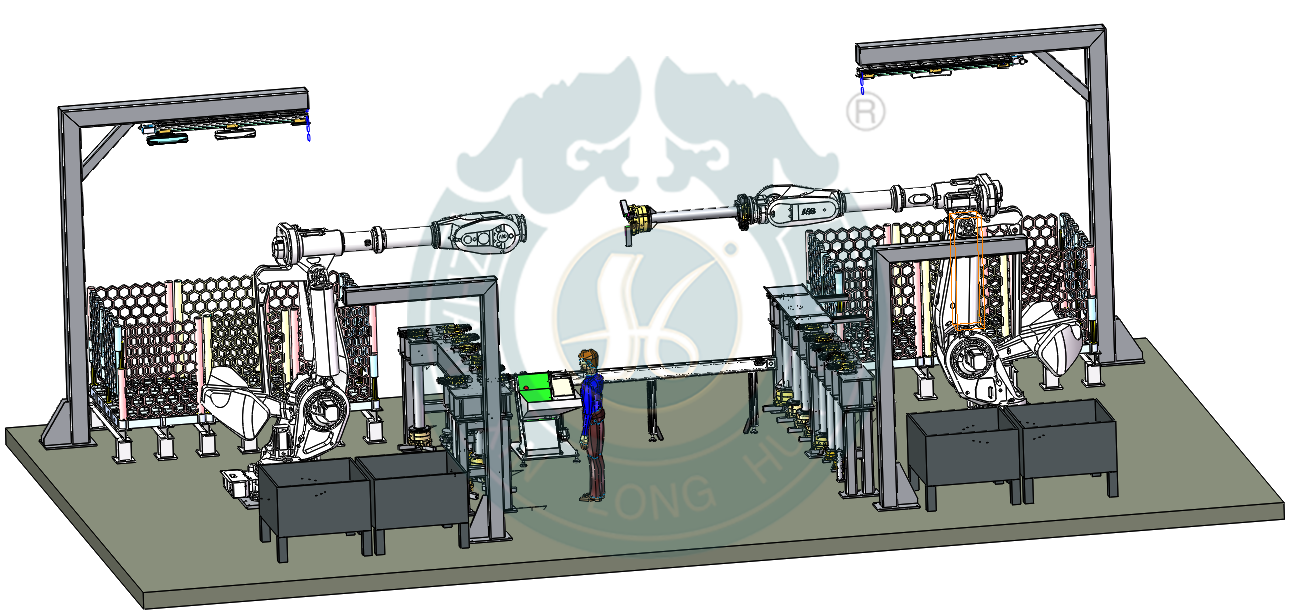

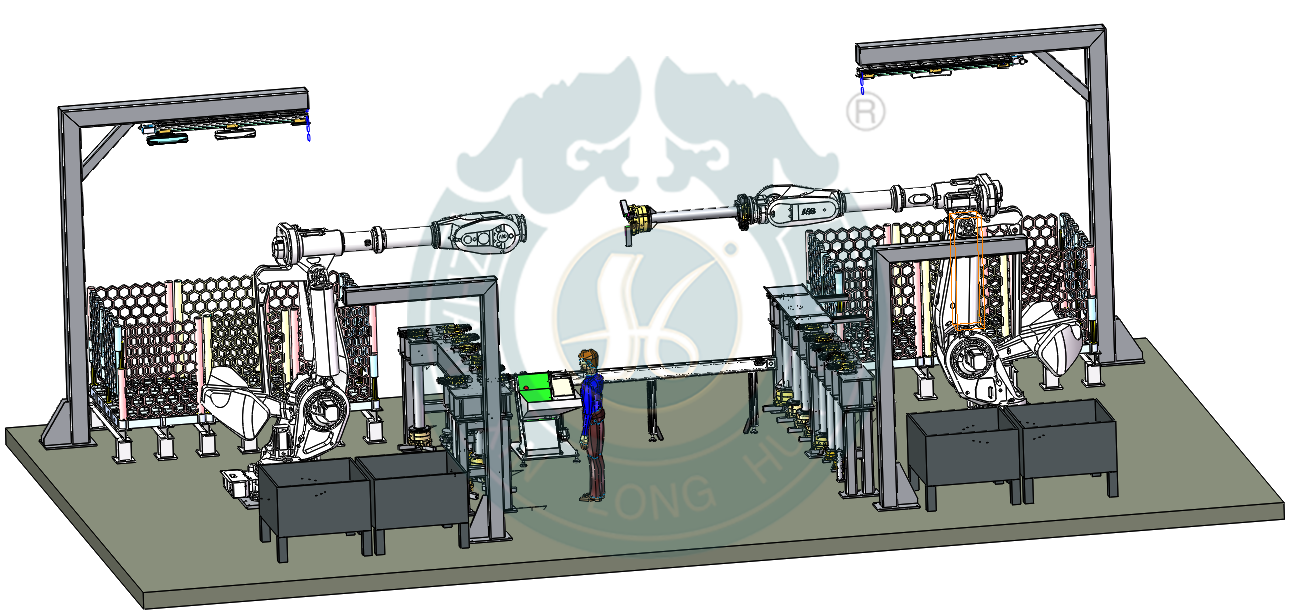

- Robot vision guided loading and unloading stacking system

Robot vision guided loading and unloading stacking system

This system integrates industrial robots, 3D visual recognition technology, intelligent grasping algorithms and yardage planning modules, and is designed for the disordered incoming scene of flange-type workpieces. Through visual perception, intelligent decision-making and precise execution, the system realizes the whole process automation of automatic identification, grasping, positioning and orderly yarding from the messy pile of workpieces, which solves the problems of low efficiency, strong labor and insufficient safety of traditional manual loading and unloading.

System Core Components

3D Visual Recognition Module

Real-time scanning of workpiece stacked areas using high-precision 3D cameras (e.g. binocular vision or structured light cameras);

Fast recognition of attitude, position and size of flange-like workpieces based on deep learning algorithms;

Generate point cloud data and compute optimal grasping points to support obstacle avoidance planning in complex stacked states.

Industrial Robot Actuator Cells

Equipped with 6-axis high degree of freedom industrial robots (e.g. Fanuc, ABB or Kuka);

End-integrated adaptive flexible clamps (e.g. electromagnetic chucks, pneumatic grippers or vacuum chucks), compatible with different flange sizes;

Supports dynamic path planning to avoid collisions and optimize movement trajectories.

Intelligent Control and Decision Systems

PLC or industrial PC based central controller to coordinate vision, robotics, conveyor lines and other modules;

Built-in workpiece database, support multi-specification flange parameters fast switching;

Real-time deskew function ensures gripping and placing accuracy through secondary vision verification.

Yardage planning module

Generation of palletizing solutions based on preset palletizing rules (e.g. number of layers, rows and columns spacing, staggered stacking);

Dynamically adjusts the palletizing sequence to suit the production beat, supporting pallet, rack or line docking.

Typical Application Scenarios

Automotive manufacturing: automated loading and unloading of engine flanges and wheel bearing flanges;

Valve Fitting Industry: Intelligent Sorting and Palletizing of Flange Body Blanks;

Construction Machinery: Unmanned Handling of Large Flange Structural Components;

Intelligent warehousing and logistics: automated three-dimensional storage and retrieval of finished flange products.

Home

Home